Pneumatic conveying

Pneumatic conveying is a comprehensive technology, which involves the fields of fluid mechanics, material science, automation technology and manufacturing technology. It is a high-tech project with high conveying efficiency, less land occupation, economy and no pollution. With the rapid development of economy, the production of all walks of life is also expanding.

The environmental pollution caused by some raw materials and powder materials in some industries, such as thermal power plants, chemical plants, cement plants, pharmaceutical plants and grain processing plants, has been paid more and more attention. Pneumatic conveying technology has been gradually popularized.

Pneumatic conveying is an important link of cleaner production. It is a process of replacing traditional mechanical conveying materials with sealed conveying pipeline. It is a modern logistics system suitable for bulk material conveying.

It will replace all kinds of traditional mechanical conveying with strong advantages. Features:

1. Pneumatic conveying is a fully enclosed pipeline conveying system.

2. The layout is flexible.

3. There is no secondary pollution.

4. High emission and energy saving.

5. It is convenient for material conveying and recovery.

6. The pneumatic conveying system has strong advantages. It will replace all kinds of traditional mechanical conveying.

7 computer control, high degree of automation

Pneumatic conveying form:

Positive pressure pneumatic conveying system: the general working pressure is 0.1 ~ 0.5MPa

Negative pressure pneumatic conveying system: the general working pressure is -0.04 ~ 0.08 MPa

According to the working principle, pneumatic conveying can be roughly divided into suction type and pressure type. Suction pneumatic conveying is to suck the atmosphere and materials into the pipeline and transport them with low air pressure air flow, so it is also called vacuum suction. Pressure pneumatic conveying uses compressed air higher than atmospheric pressure to push materials for conveying.

Suction and delivery characteristics

1. It is suitable for centralized transportation from several places to one place. The feeding point can be one or several, and the material pipe can be equipped with one or several branch pipes. Not only can the materials from several feeding points be transported to the unloading point in turn, but also the materials from several feeding points can be transported to the unloading point at the same time.

2. Under the action of negative pressure, the material is easy to be inhaled, so the feeding at the throat is simple. The hopper can be open for continuous feeding and conveying.

3. When the materials are transported under negative pressure, the moisture is easy to evaporate, so the materials with high moisture are easier to transport than the pressure type; The materials supplied under heating state can be cooled by transportation.

4. The components shall be kept sealed, and the structures of domestic separators, dust collectors, air locks and other components are relatively complex.

5. The side channel blower is set at the end of the system and requires a high degree of air purification.

Pressure feeding characteristics

1. It is suitable for dispersed transportation from one place to several places. That is, the feeding point is one, and the unloading point can be one or several.

2. Compared with the suction type, the concentration and conveying distance can be greatly increased.

3. Under positive pressure, materials are easy to be discharged from the discharge port, so the structure of separator and dust collector is simple, and air lock is generally not required.

4. The blower or air compressor is at the head end of the system and has low requirements for air purification.

5. Under the action of positive pressure, the material is not easy to enter the conveying pipe, so the structure of the feeding device is complex.

Application of high pressure side channel blower in pneumatic conveying

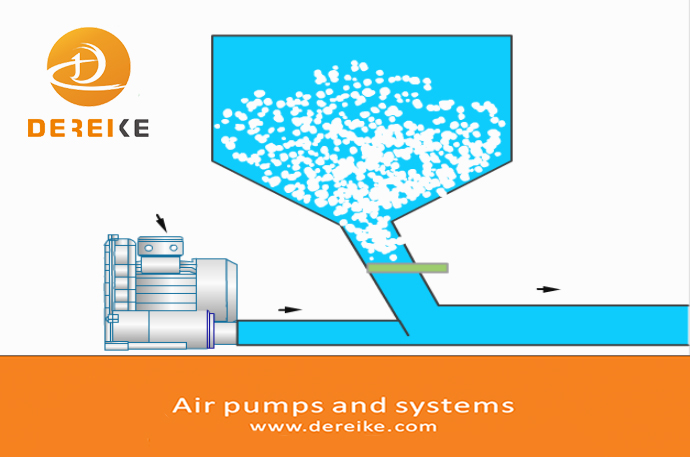

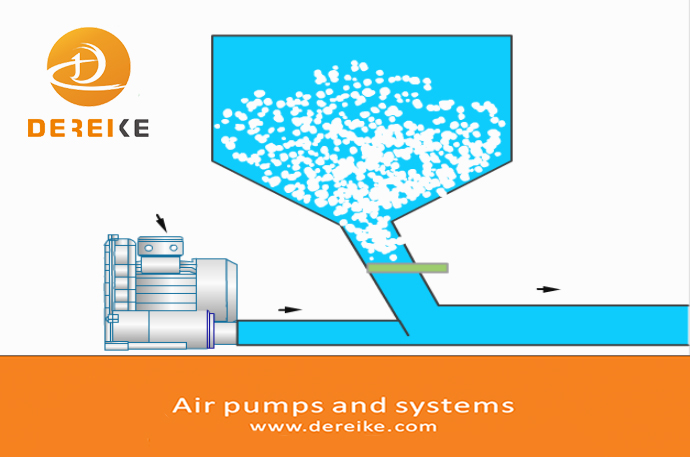

The high-pressure side channel blower is the core equipment in the pneumatic conveying system. It is mainly the suction or blowing force generated by the operation of the high-pressure side channel blower to provide the source power for the pneumatic conveying system!

(1) Suction pneumatic conveying device (negative pressure), which causes negative pressure in the pipeline by the blower to make the finished materials move;

(2) Pressure pneumatic conveying device (positive pressure) makes materials move in the pipeline due to the action of compressed air in the pipeline;

(3) In the mixed pneumatic conveying device (positive pressure and two negative pressure), part of the conveying pipeline is in the pressure conveying state, while the other part is in the negative pressure state, or the material moves in one direction under the action of pressure, and the return movement depends on the negative pressure in the pipeline.

Dereike Intelligent M&E Equipment

Our's main products:Side channel blower,Turbo blower,High speed blower,Belt drive type blower,side channel blower,Anti-explosion blower,air knife,air filter,vaccum filter,muffler,pressure relief valve.etc.

And can be used in these applications:water treatment,central dust collection,biogas,automatic feeders,environmental protection,paper cutting,industrial machines,textile,and filling.