With air blowers representing a massive percentage of electricity costs in wastewater remedy plants, the race is on to find greater green aeration methods. What will the arrival of screw technology mean for rotary lobe designs? Peter Lattaway discusses laboratory checks that as compared the two.

Low strain air is the spine of many production methods and is a important element inside the aeration operations of wastewater treatment plants. However, the technical evolution in blower design for small quantity flows (three hundred to 5,000m³/h) has not superior for the beyond 50 years. While Roots-kind lobe blowers were evolved from 2-lobe to 3-lobe blowers, mainly to lessen the pulsation level, lobe blowers have not achieved good sized enhancements in terms of energy performance.

In order to achieve that energy efficiency goal, a chief advance within the layout principle became needed.

That essential innovation became the introduction of blowers using internal compression as opposed to external compression. By designing compressor screws devoted for low stress (0.5bar(e)), dramatic energy savings are achieved resulting from improved electricity performance and lower air outlet temperatures.

Dereike Intelligent M&E Equipment

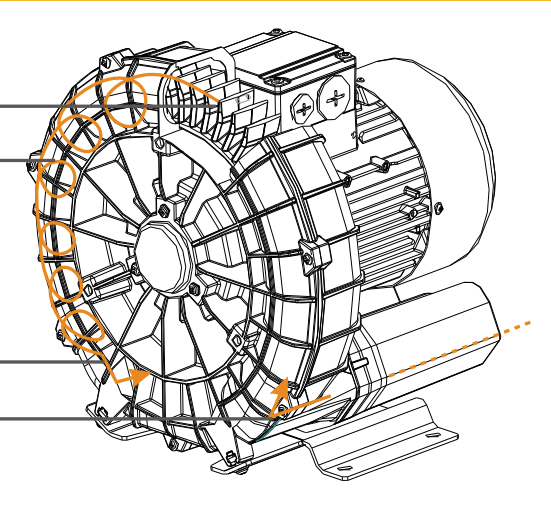

Our's main products:Side channel blower,Turbo blower,High speed blower,Belt drive type blower,Anti-explosion blower,air knife,air filter,vaccum filter,muffler,pressure relief valve.etc.