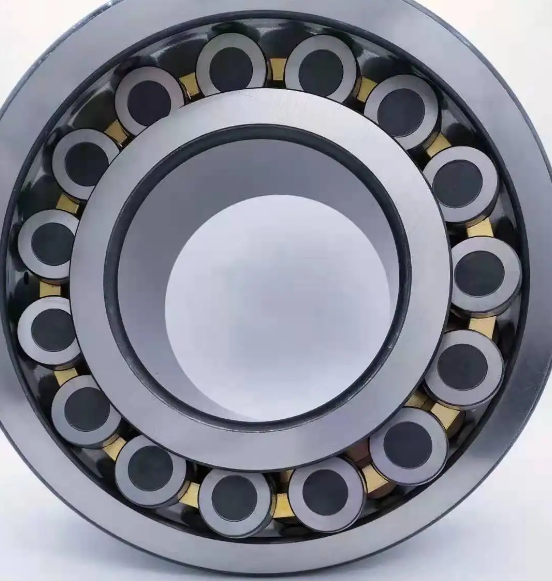

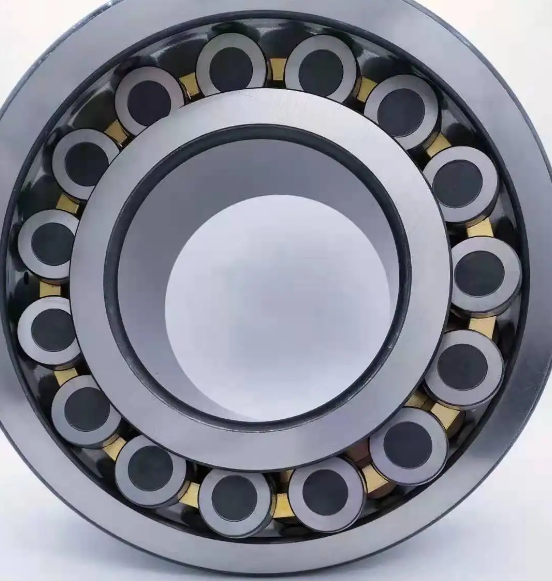

The use of side channel blower can not be separated from the coordinated use of bearings, bearing of side channel blower can not be replaced by other components, so it is very important to ensure that it can play a normal role in use, but also an important direction to ensure the efficiency of side channel blower. How can the bearings of side channel blower be well protected?

The guide to tell you how to bearing maintaince of side channel blower

1.Clean the bearings: Regularly clean the bearings to keep them in good condition. Use appropriate tools and cleaning agents to gently wipe the bearing surfaces, removing accumulated dirt and grease. Make sure no dust or other impurities enter during the cleaning process.

2.Lubricate the bearings: Proper lubrication of the bearings is crucial to reduce friction and wear. Use the recommended lubricating grease or oil according to the manufacturer's guidelines. Ensure the bearings are cleaned before applying lubricant and add the lubricant in the correct locations and quantities.

3.Monitor bearing temperature: Periodically check the operating temperature of the bearings to ensure they stay within the normal range. If the bearing temperature abnormally rises, it could indicate inadequate lubrication or bearing failure. Promptly investigate and resolve any temperature elevation issues to prevent damage to the bearings or other equipment.

4.Inspect bearing fasteners: Regularly inspect bearing fasteners, such as screws and nuts, to ensure they are properly tightened. Loose fasteners can lead to vibration and bearing damage. If any loose fasteners are found, tighten them immediately or replace them.

5.Dust and seal protection: Ensure that the seals and dust protection devices around the bearings are functioning properly. Prevent dust, dirt, and other impurities from entering the interior of the bearings, which can affect their proper operation. Replace any damaged seals or dust protection devices as necessary.

6.

Regular inspection and maintenance: Conduct comprehensive inspections and maintenance on a regular basis, including cleaning, lubrication, fastener checks, and seal inspections of the bearings. Develop a maintenance schedule according to the manufacturer's recommendations and adhere to it to ensure the bearings operate smoothly.

Therefore, the maintenance of high-pressure fan bearings is not a simple matter. Once the user neglects which point is not done well, the bearing of the fan still has a great risk. Therefore, when using the fan, we must check the safety of the bearing of the fan beforehand to ensure that the fan is started after the error is made, so that the fan can also be started in this way. Fully play a role in the use.