Papermaking wastewater refers to the wastewater produced in the process of pulping and papermaking. Including pulping and cooking waste liquid, washing waste water, bleaching waste water and paper machine white water, etc

summary

The production of paper industry is divided into two main process stages, namely pulping and papermaking. Pulping is to separate the fibers from plant raw materials, make pulp, and then bleach; Papermaking is to dilute, shape, press, dry and make paper. Both processes consume a lot of water. In China, the production of 1 ton of paper requires about 100 tons (wood pulp) to 400 tons (straw pulp), most of which are discharged as waste water. Papermaking wastewater contains high concentrations of BOD (biochemical oxygen demand) and SS (suspended solids), as well as a large number of chemicals and impurities.

The waste water produced by pulping is seriously polluted. The wastewater discharged during pulp washing is dark brown, which is called black liquor. For each ton of pulp produced, about 10 tons of black liquor with 10 Baume degrees (10 ° be ') will be discharged. The concentration of pollutants in black liquor is very high, BOD is as high as 5000~40000 mg / L, and the total amount of fiber is sometimes as high as more than 15% of the total amount of products. It also contains a lot of inorganic salts and pigments. The waste water discharged from bleaching process also contains acid, alkali and other substances. In the papermaking process, the waste water discharged from the front end of the papermaking machine is called white water, which contains a lot of fibers and fillers and adhesives added in the production process, most of which are useful substances. Black liquor and white water are the main wastewater of paper industry.

At present, the widely used black liquor treatment method is combustion method to recover sodium hydroxide, sodium sulfide, sodium sulfate and other sodium salts combined with organic matter. First, use vacuum washer or pressure washer to extract the black liquor from the cooked pulp, and then evaporate and concentrate the black liquor to a solid content of more than 45% through a 3-effect to 5-effect evaporator, and then send it to the combustion furnace. In the combustion furnace, add sodium sulfate and burn at 1100 ℃. The function of combustion is to continue to evaporate the water in the black liquor and promote the decomposition of sodium salt in the black liquor when heated. In the combustion furnace, organic matter and air are mixed and burned, and inorganic matter becomes molten matter. Organic impurities are decomposed as follows:

NaOR+O2──→Na2O+CO2+H2O

Na2O + CO2 - → Na2CO3, where R is an organic group, and H and C are produced by the combustion of R. Sulfate reacts with carbon to reduce to sodium sulfide:

Na2so4+2c - → the melt of na2s+2co2 black liquor after combustion can be dissolved in water. The solution is called green liquor, and the main component is sodium carbonate. Add lime to the green liquor for causticization to obtain sodium hydroxide:

Ca (OH) 2 + Na2CO3 - → 2naoh + CaCO3 ↓ this method is suitable for treating alkaline papermaking wastewater with wood as raw material, but not with grass fiber as raw material. Grass raw materials have fine fibers, high hemicellulose content and silicon. Because the fiber is small, the water consumption when extracting black liquor is large; During evaporation, silicate will scale, which will reduce the heat transfer coefficient and even block the pipeline. Straw pulp black liquor is relatively viscous, and it is difficult to reach the concentration required for combustion after evaporation, so auxiliary fuel needs to be added. The melting point of sodium silicate (1088 ℃) is higher than that of sodium carbonate (874 ℃), which will promote a large amount of volatilization of sodium carbonate. In addition, during the causticization of sodium carbonate, due to the interference of the formed sodium silicate, calcium carbonate is not easy to sink, reducing the causticization efficiency. Therefore, straw pulp black liquor cannot be widely used at present.

Folding method

The black liquor of ammonium fertilizer process contains a large amount of alkali, and the general pH value is above 10. Add waste acid to the black liquor, adjust the pH value to 1~2, and then add ammonia to neutralize it to neutral, that is, humic acid amine, which contains about 1% ammonia and is in liquid state. It is used as agricultural fertilizer, with high and lasting fertilizer efficiency, and can promote soil porosity. This treatment method has less investment and great effect, and is simple and easy to operate.

In the method of making phosphate fertilizer, the black liquor is evaporated and concentrated to a concentration of 25 Baume degrees, which is burned together with phosphorite and sylvite at a temperature of 1100 ℃. Part of the heat in the black liquor and sodium carbonate generated during high-temperature combustion are used to make phosphate fertilizer. This phosphate fertilizer has good fertilizer effect. The equipment investment of this method is large, and some useful components in black liquor cannot be recovered.

Since the 1960s, China has begun to use electrodialysis to comprehensively utilize the black liquor of alkaline pulping. The recovery rate of alkali can reach more than 70%; Organic anions are gradually oxidized into organic acids by anodic reaction; Lignin can be recycled after precipitation.

After dealkalization and lignin separation, the black liquor can adjust its pH value and neutralize it with ammonia to become humic acid amine. This method can recycle a large amount of useful substances in black liquor without generating new waste, but the power consumption is too large. The power consumption for recycling 1 ton of caustic soda is about 5000 kwh.

Bleaching wastewater treatment pulp generally needs three-stage bleaching process. In the chlorination section, acidic wastewater is produced; In the alkali treatment section, alkaline wastewater is generated; In the bleaching section, oxide wastewater is produced. These wastewater can be mixed with paper machine wastewater for treatment. The main treatment methods are:

The physical method mainly removes the suspended solids in the wastewater, such as knots, bark, pulp residue, fiber, filler, rubber and coating, through filtration, sedimentation, floating and other methods. Generally, it can remove more than 80% of suspended solids and about 50% of COD (chemical oxygen demand).

Biological methods include activated sludge method, biofilm method, etc. If possible, organic matter can also be removed by oxidation pond method or in aeration tank.

Chemical methods include neutralization, oxidation and deodorization. Neutralization treatment is often used to adjust the pH value before clarification, so that bleaching wastewater can meet the conditions required for biological treatment. It can also be neutralized before wastewater discharge to meet the discharge requirements. Bleaching wastewater is often deodorized and decolorized in the front or rear stage of biological treatment.

In addition, there are adsorption and coagulation methods to decolorize and remove suspended and colloidal substances. For example, a large amount of organic matter can be removed by using lime, activated carbon or coagulation sedimentation. Some countries also use reverse osmosis, ultrafiltration, electrodialysis, ion exchange and other treatment methods.

The waste water produced by white water treatment paper making is the water (white water) separated from the diluted pulp in the case roll part of the paper machine, which contains a large amount of pulp fiber, kaolin, talc and other fillers and rosin. White water can be directly sent back to the pulp dilution tank for reuse, and both water and raw materials have utilization value. The waste water sucked out of the suction tank and the waste water squeezed out contain less components and fibers than white water, which can be sent to the beater for recycling, or the fibers and fillers in it can be recycled by separation method. The separation method is to filter with a screen, and then treat with sedimentation and air flotation. This method can reduce the suspended solids to 15~20ppm, the fiber recovery rate is more than 90%, and the treated water can be reused.

The wastewater from acid papermaking is acidic, with high BOD and strong color, including sugar, hexose, lignin, etc. Wood pulp wastewater can be neutralized and fermented, and alcohol can be made from sugar. About 1kg alcohol can be made from each ton of wastewater. The wastewater can also be concentrated and directly made into adhesives (such as reed pulping wastewater), dispersants, tanning agents, or by-products such as processing and extracting feed yeast, thiolignin, vanillin, etc. The economic effect of these methods is not ideal, there are still technical problems, and they have not been popularized. Countries generally use combustion method to recover heat and chemicals such as magnesium salt. The treatment of paper industry wastewater should mainly focus on improving the rate of circulating water use, reducing water consumption and wastewater discharge. At the same time, we should actively explore various reliable, economic and perfect treatment methods that can make full use of useful resources in wastewater.

Papermaking wastewater treatment

Papermaking wastewater treatment refers to the treatment method of wastewater generated in the papermaking industry. Papermaking wastewater mainly comes from the two production processes of pulping and papermaking in the papermaking industry. 1. Pulping is to separate the fibers from plant raw materials, make them into pulp, and bleach them into pulp; 2. Papermaking is to dilute, shape, press, dry, copy and process the pulp into paper.

essential information

edit

Straw and wood pulp are mostly used as raw materials in China's paper industry. Pulp and paper production generally consists of pulping, washing, bleaching and papermaking processes. Pulping in paper industry includes alkaline pulping, chemical mechanical pulping and mechanical pulping. According to different pulping methods, raw materials, pulping yield, papermaking varieties and whether there is chemical recovery, the occurrence and discharge of pollutants are very different, but basically they all contain a large amount of suspended solids, BOD, COD and some toxic substances, which are usually treated by the combination of physicochemical and biological methods.

source

(1) The waste liquid generated by cooking wood pulp (or straw pulp), also known as black liquor.

(2) The waste water discharged from the beating machine and the refining machine is called beating waste water.

(3) Paper machine wastewater, which can be used directly, is called white water.

characteristic

Papermaking wastewater has complex components and poor biodegradability. It belongs to industrial wastewater that is difficult to treat. The main pollutants contained in it are as follows:

(1) Suspended solids: including settleable suspended solids and non settleable suspended solids, mainly fibers and fiber fines (i.e. broken fiber fragments and miscellaneous cells).

(2) Easily biodegradable organics: including low molecular weight hemicellulose, methanol, acetic acid, formic acid, sugars, etc.

(3) Refractory organics: mainly from lignin and macromolecular carbohydrates contained in fiber raw materials.

(4) Toxic substances: rosin acid and unsaturated fatty acid contained in black liquor.

(5) Acid base toxicants: the pH value of alkaline pulping wastewater is 9-10, and the pH value of acid pulping wastewater is 1.2-2.0.

(6) Chromaticity: the residual lignin contained in pulping wastewater is highly colored.

harm

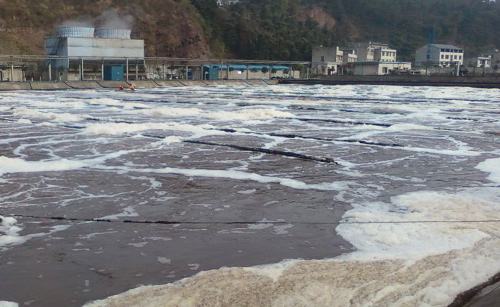

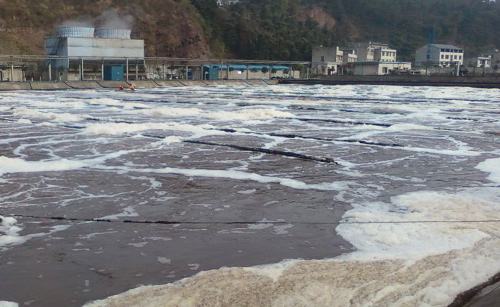

Although papermaking wastewater is also recycled, treated and reused in the production process, a large amount of wastewater is still discharged into the water body, causing serious pollution of the water environment. Papermaking wastewater is complex in composition and contains a large amount of lignin, hemicellulose, sugars and other dissolved substances (residual alkali, inorganic salts, volatile acid, ammonia nitrogen, etc.). If it is discharged into the receiving water body without treatment, it will not only consume dissolved oxygen and affect the survival of aquatic organisms, but also change the physiology and biochemistry of organisms, community results and internal tissues, and is vulnerable to the invasion of various harmful microorganisms, making the biological quantity of aquatic organisms Quality degradation.

government

Process selection

The selection of process scheme is very important for the construction of wastewater treatment facilities, ensuring the treatment effect of treatment facilities and reducing operating costs. Therefore, the overall process scheme and implementation mode should be optimized after comprehensive technical and economic analysis in combination with the design scale, wastewater quality characteristics and local actual conditions and requirements.

In the determination of the overall process plan for wastewater treatment, the following principles should be followed:

(1) The selected process must be technologically advanced and mature, with strong adaptability to water quality changes and stable operation, and can ensure that the effluent quality can meet the requirements of factory use standards and national wastewater discharge standards.

(2) The selected process should reduce capital investment and operation costs, save floor space and reduce energy consumption.

(3) The selected process should be easy to operate, flexible and easy to manage. According to the quality and quantity of influent water, the process operation parameters and operations should be adjusted appropriately.

(4) The selected process shall be easy to realize automatic control and improve the operation management level.

(5) The selected process should greatly reduce the adverse effects on the surrounding environment (odor, noise, mist, etc.).

Common pretreatment methods

The pretreatment process is mainly composed of grid, screen, fiber recovery system, regulating water volume and quality and other processes. Different pretreatment methods can be adopted according to different paper industry wastewater quality to remove some pollutants and improve wastewater quality, so that the treatment effect of the whole wastewater treatment system can be achieved.

Main treatment methods

The concentration of SS and COD in waste paper and papermaking wastewater is high, and COD is composed of insoluble COD and soluble COD. Generally, insoluble cod accounts for most of the total amount of COD. When SS is removed from wastewater, most of the insoluble cod is removed at the same time. Therefore, the main problem to be solved in the treatment of waste paper and papermaking wastewater is to remove SS and cod. There are mainly the following methods:

(1) Air flotation or sedimentation method. By using air flotation or sedimentation method and adding coagulant, most SS, most insoluble COD and some soluble COD and BOD5 can be removed at the same time.

(2) Combination of physicochemical and biochemical treatment. For large and medium-sized waste paper enterprises with low discharge of papermaking wastewater and high COD content in wastewater, it is expected that it will be more difficult to achieve the national first-class discharge standard through single-stage air flotation or sedimentation physicochemical methods, because soluble COD and BOD5 can be effectively removed mainly through biochemical methods. Generally, physicochemical and biochemical treatment methods are adopted.

(3) Sludge disposal and comprehensive utilization. The loss of pulp in the papermaking process is inevitable. There are two advantages to recycling the waste pulp flowing into the wastewater: first, the recovered pulp can be reused for papermaking or sold as the raw material of low-grade paper, resulting in direct economic benefits; The second is to reduce the load of wastewater treatment and reduce the consumption of chemicals.