As the first treatment step of sewage treatment facilities, aerated sand catcher is an important process step to optimize and economically treat sewage.

Separating sand and other mineral materials can protect the downstream purification process from abrasion, blockage and sediment damage.

Separating sand and other mineral materials can protect the downstream purification process from abrasion, blockage and sediment damage. In the sand catcher of the poppenweiler wastewater treatment facility in Ludwigsburg, Germany, the mink claw variable frequency compressor of dr.-ing company optimizes the separation efficiency of sand and grease. k . Dereike GmbH is a. This can be achieved without modifying the geometry of the bunker.

Wastewater treatment equipment poppenweiler

The poppenweiler wastewater treatment facility has a population equivalent (PE) of 31000 people and is part of the internal operations of the Ludwigsburg municipal drainage service, which also includes sewage treatment plants in the eglosheim district (18500 PE) and hoheneck district (167000 PE). Sewage treatment facilities were put into use in 1976, and were greatly expanded and modernized from 1994 to 1996. The reason is that the old wastewater treatment facilities can no longer meet the requirements of purification performance, mainly due to the decomposition of nitrogen and phosphorus. In addition, afterbach and Marbach siegelhausen communities are also connected to the poppenweiler wastewater treatment facility. Today, this 31000 PE level 4 wastewater treatment facility covers an area of 342 hectares.

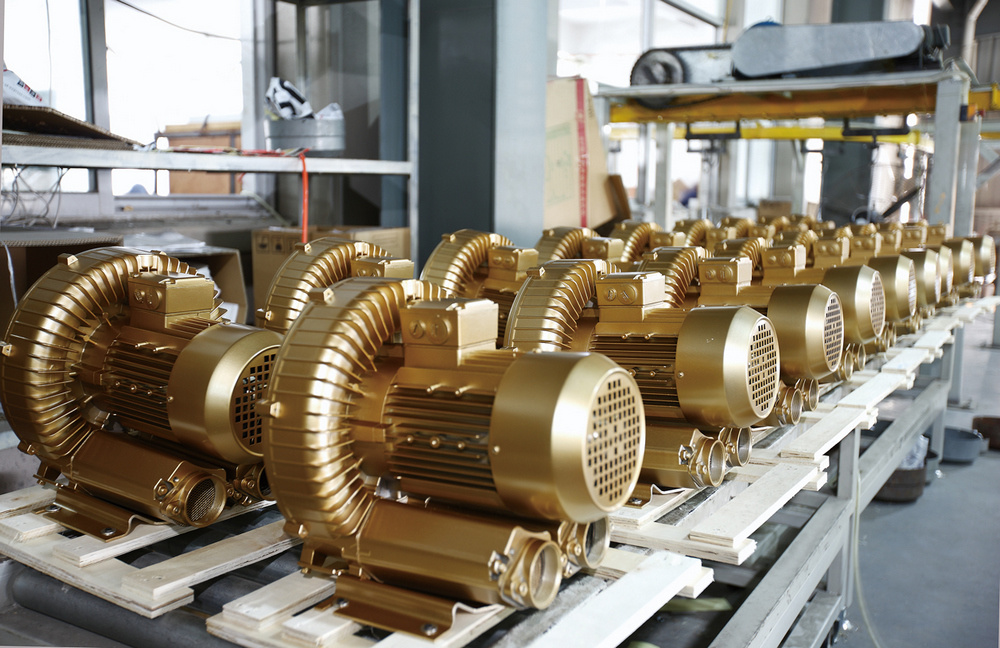

The 15m Changsha pit (Figure 1) in 1976 is still in use. In the expansion and modernization measures of the 1990s, it did not expand, so it reached the limit of its output. This becomes apparent due to the deposition of sand in the primary clarifier and downstream aeration tank. This is why Walter Eichinger, the operation manager of all three sewage treatment facilities of Ludwigsburg municipal drainage service, began to look for a solution to optimize the separation output of sand catchers as economically as possible.

According to the guidelines of the German water, wastewater and Waste Association (DWA), Helmut riegraf, the project manager of municipal drainage services in Ludwigsburg, calculated the necessary size of a sand trap that can best separate sand and suspended substances, such as oil and grease, from organic suspended substances. As a result, the sand catcher needs to be at least 3 meters long to reduce the flow rate and achieve the best separation. Due to the large construction cost and downtime required to extend the use of the sand trap, Walter Eichinger and Helmut riegraf considered the scheme of optimizing the wastewater circulation through aeration.

They want to change the turbulent kinetic energy caused by the rolling speed in the wastewater by changing the air flow. So they want to use the flow rate to affect the vertical circulation and forward movement of wastewater caused by aeration.

Bush overpressure solution and its benefits to customers

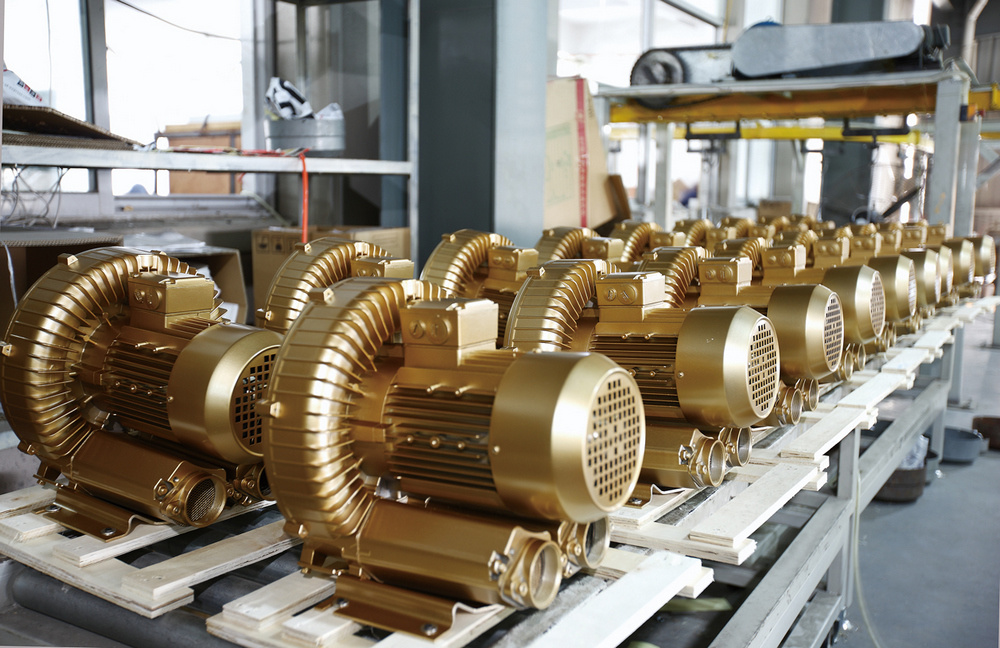

The installed rotary lobe blower is not adjustable, so it provides a constant volume flow at an overpressure of 0.5 bar. At that time, Walter Eichinger contacted Dr Ing company. k . Dereike GmbH is a. The company recommends installing an external variable speed drive mink jaw compressor (Figure 2). The compressor can also provide a constant overpressure of 0.5 bar, but the volume flow can be adjusted by the frequency converter, which can be accurately adjusted according to the requirements of the existing sand catcher. Using the working principle of claw compressor, it can be adjusted in a wide range of 20 ~ 60 Hz without affecting the overpressure.