At present, the European Union, the United States, China, and other major economies worldwide have legislated mandatory adoption of IE4 efficiency standards for electric motors. For example, starting from May 2025, the EU will require all motors to meet IE4 levels, while China will implement an even stricter permanent magnet motor standard by October 2025. Combined with the dual pressures of carbon reduction targets and rising energy costs, low-efficiency motors face the risk of rapid elimination.

The transition from IE3 to IE4 has thus become a compulsory step for the motor industry to respond to policy, reduce energy consumption, and maintain market competitiveness.

According to international standard IEC 60034-30-1, the efficiency gain when upgrading from IE3 to IE4 motors is typically in the range of 1.2% to 2.8%, depending on power rating. For example:

2.2 kW, 4-pole motor: IE3 efficiency 86.7%; IE4 requires 89.5% (an increase of 2.8%)

90 kW, 4-pole motor: IE3 efficiency 95%; IE4 requires 96.2% (an increase of 1.2%)

The motor efficiency formula is:

Efficiency = (Output Power / Input Power) × 100% = [Output Power / (Output Power + Total Losses)] × 100%

Upgrading to IE4 essentially means reducing total losses. Based on calculations, total losses typically fall by 7% to 25%.

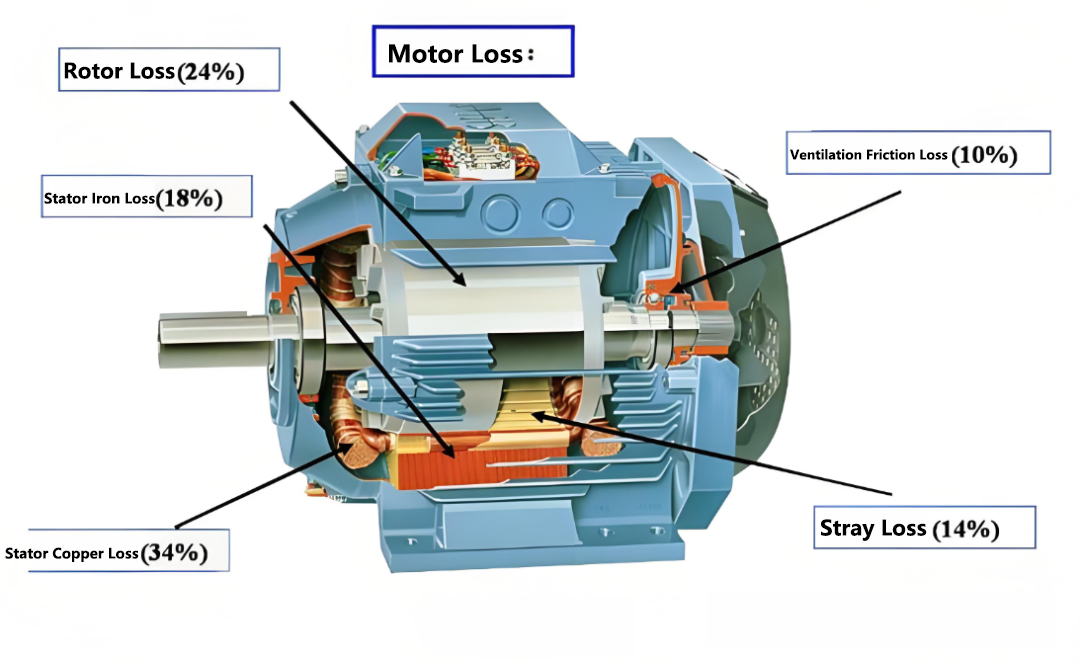

Motor losses can be described as five “hidden thieves” of electricity:

Stator copper loss (resistance heating in stator windings)

Rotor copper loss (resistance heating in rotor conductors)

Iron loss (energy wasted in magnetizing and demagnetizing the iron core)

Mechanical loss (friction, fan resistance, and bearing drag)

Stray load loss (harmonic currents, leakage flux, etc.)

Copper losses (stator + rotor): 40%–55%

Iron losses: 20%–35%

Mechanical losses: 5%–15%

Stray losses: 5%–10%

Increase slot fill factor

Use thinner insulation, more precise winding methods, or switch from round wires to flat conductors.

The principle: higher copper cross-sectional area reduces resistance, thereby lowering copper loss.

Shorten end windings

End windings do not contribute to output power but add resistance and heat. Shorter designs reduce wasted energy.

Reduce air gap

Smaller gaps between stator and rotor reduce magnetizing current requirements, lowering stator heating.

Cast copper rotor

Replacing aluminum rotor bars with copper reduces resistance by ~40%, directly lowering rotor copper loss.

Permanent magnet rotor

By embedding permanent magnets, synchronous motors eliminate the need for rotor currents, thereby nearly removing rotor copper loss altogether.

Use higher-grade silicon steel laminations

Replace 0.5 mm laminations (e.g., 50W470) with 0.35 mm thin laminations (e.g., 35W270).

Thinner materials reduce hysteresis and eddy current losses significantly.

Optimize slot geometry

Adjusting slot shapes (semi-closed, rounded edges, or pear-shaped) smooths magnetic field distribution and reduces iron losses.

Extend core length

Longer stator cores increase cross-sectional area, reducing flux density and lowering iron losses.

Increase core diameter

A larger diameter also reduces flux density, further minimizing iron losses.

Optimize or eliminate cooling fans

IE4 motors produce less heat, allowing smaller or no fans. This reduces frictional drag and windage loss.

Improve cooling structures

Enhanced cooling fins or redesigned housings dissipate heat more effectively, keeping winding resistance lower and cutting copper losses.

Optimize winding turns and layout

Short-pitch and fractional-slot concentrated windings minimize harmonic distortion and magnetic irregularities.

Skewed rotor slots

Tilting rotor slots averages out harmonic interactions between stator and rotor teeth, reducing stray losses and noise.

While the above principles apply to motors broadly, they are particularly critical in side channel blowers (also known as regenerative blowers). These blowers rely on continuous motor-driven operation to generate both suction and pressure. Motor efficiency directly determines blower performance, operating cost, and long-term stability.

Energy Efficiency: Side channel blowers often run continuously in applications like wastewater aeration, pneumatic conveying, and packaging. Upgrading to IE4 motors significantly reduces electricity consumption across thousands of operating hours.

Thermal Stability: With lower copper and iron losses, IE4 motors generate less heat. This improves blower reliability, especially under high-duty cycles.

Compact High-Speed Designs: Permanent magnet motors enable higher rotational speeds in side channel blowers, achieving higher pressure and flow without requiring larger equipment.

Compliance and Market Demand: Many industries now demand IE4-class blowers for both regulatory and sustainability goals.

Wastewater treatment: Continuous aeration blowers benefit from IE4 efficiency, lowering operational energy costs.

Food and beverage: Explosion-proof IE3/IE4 motors paired with side channel blowers ensure safety in dust-prone environments.

Medical and lab equipment: Compact IE4 motors reduce noise and heat, enabling quieter blower operation.

The shift to IE4 motor technology is reshaping both the motor and blower industries. Reducing copper, iron, mechanical, and stray losses is not just a matter of engineering optimization—it has direct implications for sustainability, regulatory compliance, and market survival.

For side channel blowers, which depend entirely on the motor’s performance, adopting IE4 or permanent magnet motors is no longer optional but essential. Whether in wastewater treatment, packaging, or cleanroom environments, the synergy of high-efficiency motors with blowers ensures lower energy use, higher reliability, and a future-proof solution.