Blowers receive a lot of attention from design engineers, suppliers, and end users. That is understandable since blowers account for more than 50 percent of the energy used in a typical wastewater treatment plant (WWTP). They represent “low hanging fruit” for energy conservation measures in wastewater treatment!

In some industries blower applications are specified with a single operating point consisting of the design flow and discharge pressure. Municipal wastewater treatment applications, however, usually require blower systems that provide a spectrum of flows and discharge pressures. Although this can be frustrating for suppliers, it reflects variability in the treatment process. Understanding the variable process demands on the system is critical to optimizing the performance of the blowers.

Sewage isn’t inherently poisonous. The destruction of aquatic life that results from wastewater discharge is caused by oxygen depletion. Microbial metabolism depletes water’s dissolved oxygen below the level needed to support aquatic organisms. Municipal wastewater processes are designed to concentrate and accelerate the metabolism of pollutants in the WWTP, minimizing the impact on the receiving water.

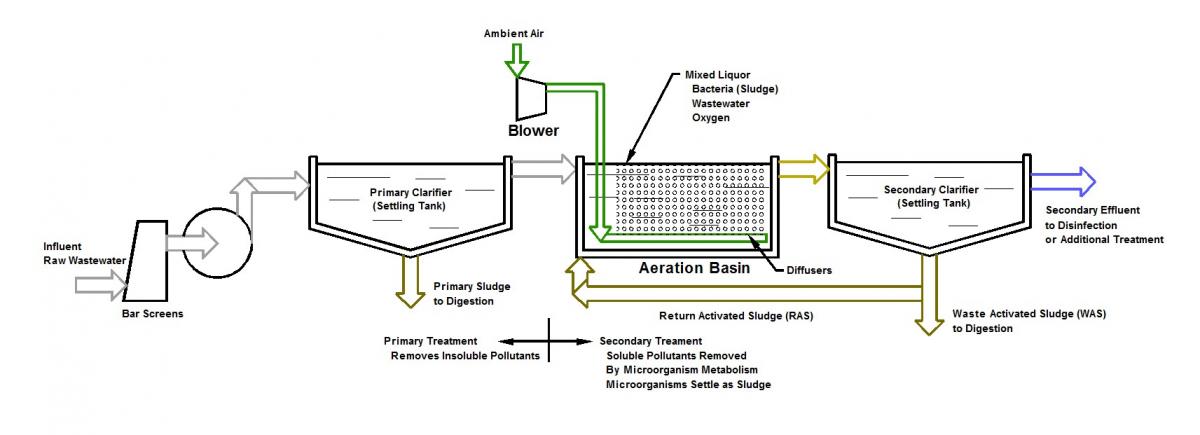

Figure 1 shows one of many process arrangements in municipal WWTPs.

Primary treatment removes solids from the wastewater. Primary treatment may include screens, grit removal tanks, and primary clarifiers. Clarifiers are essentially large basins where low turbulence allows solids to settle to the bottom for removal to additional treatment. The wastewater then goes to secondary treatment. Secondary aeration is the principal WWTP application for blowers.

In the aeration basin microorganisms (sludge), a food source (pollutants in the wastewater flow), and oxygen are brought together. This results in controlled metabolism of the pollutants. The oxygen is typically supplied by blowers and the air is bubbled into the bottom of the basin.

From the aeration basin the wastewater flows into another set of clarifiers. Treated wastewater passes out for additional treatment and/or disinfection. Most of the settled microorganisms are returned to the aeration basins to continue metabolizing pollutants. They are referred to as Return Activated Sludge (RAS). Reproduction of microorganisms in the aeration process produces an excess population, which is removed as Waste Activated Sludge (WAS).