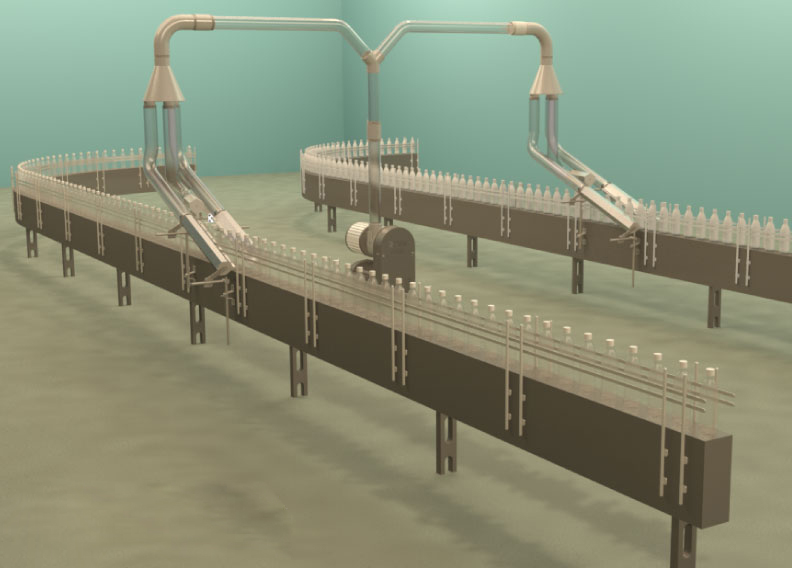

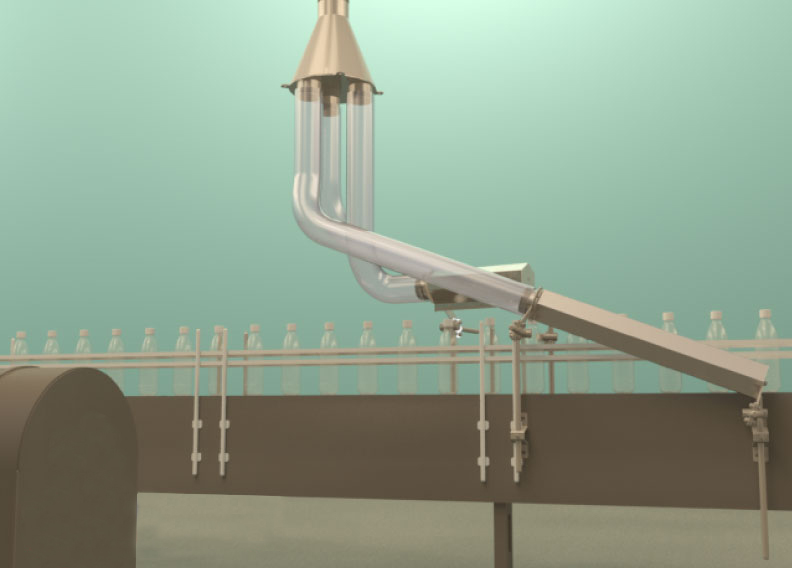

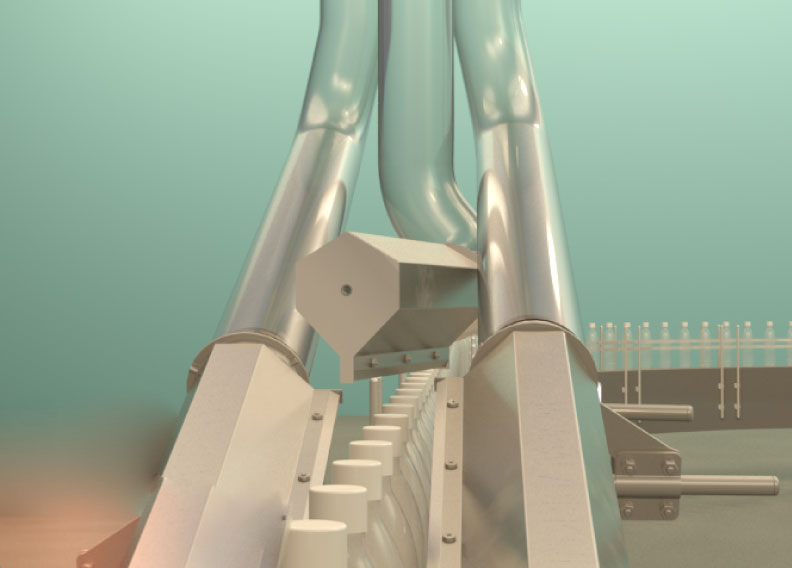

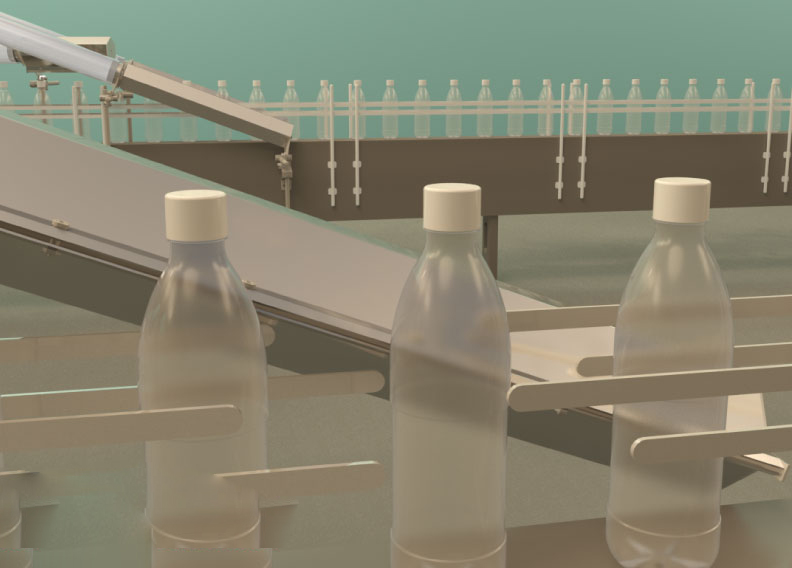

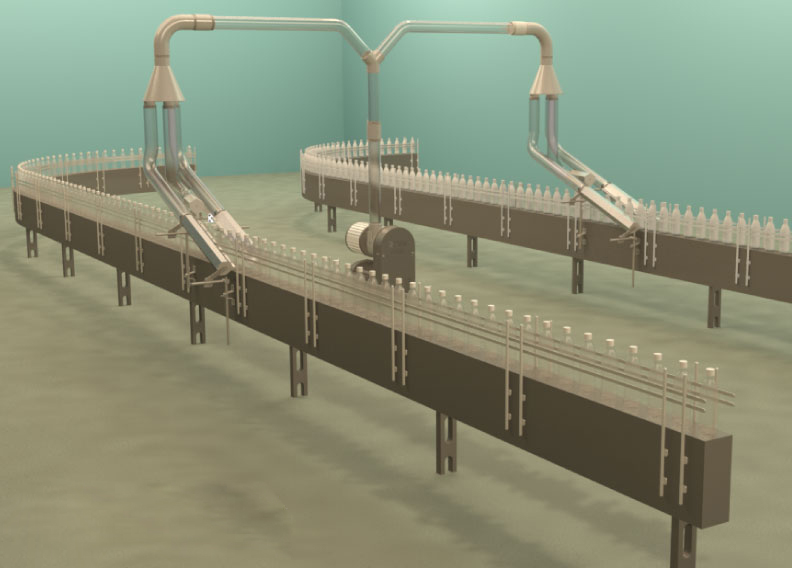

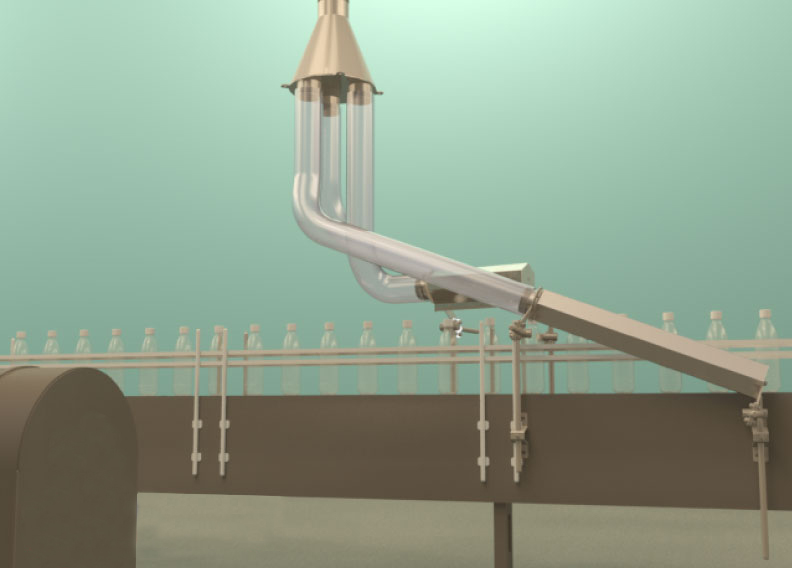

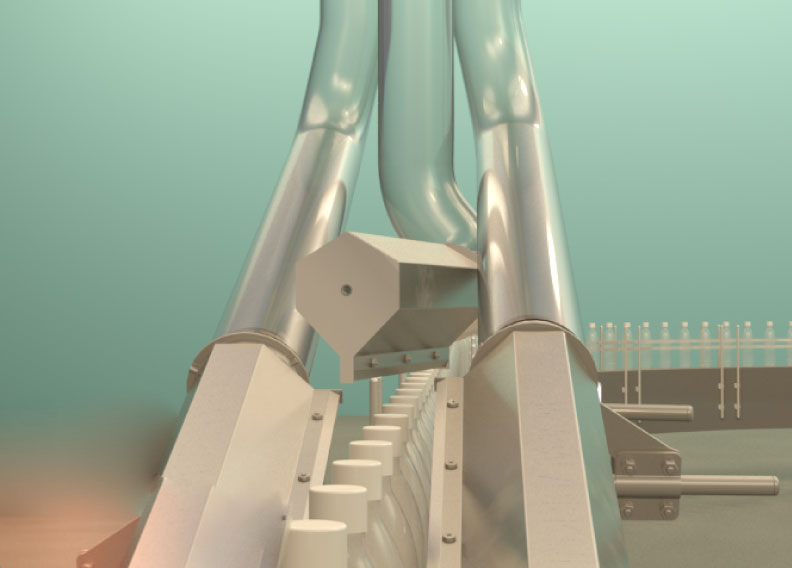

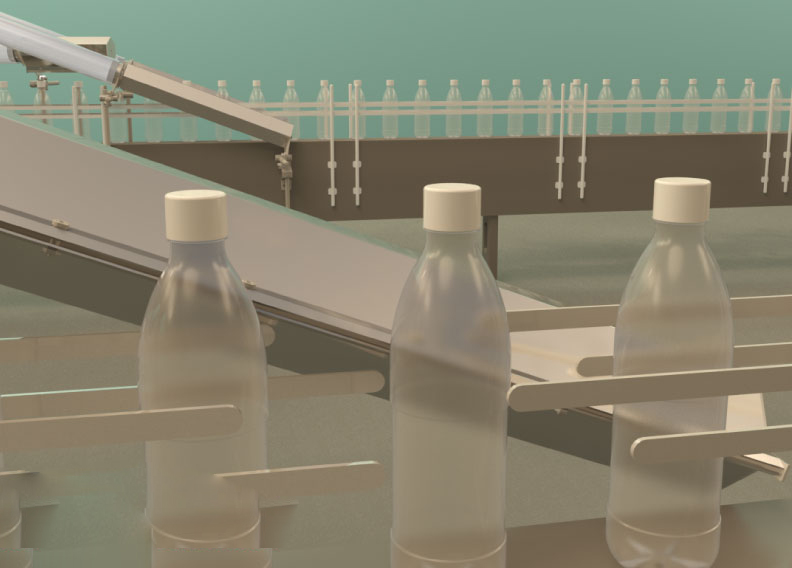

In the highly competitive canned and bottled beverage market, the perfection of product packaging is almost as important as the beverage itself. Dereike air knife drying system is a kind of air knife system which can ensure 100% water removal from bottles (cans) to avoid bad beverage labeling or spray printing. The production rate ranges from 100 to 2000 cans/min (CPM). RAETTS assures you that there will never be any moisture residue, which will lead to poor labeling, labeling, dry bathing of bottle caps, sealing, rust prevention, product hygiene, spray printing, shrinkage film or packaging cartons.

The material fermented by high-pressure fan composting system is a good organic fertilizer. Bioorganic fertilizer can be produced through organic fertilizer processing. On the one hand, the aeration system of high-pressure fan installed at the bottom of fermentation tank is used to supply oxygen by forced ventilation to avoid the formation of anaerobic environment and volatilization of water during composting process; on the other hand, the fermentation material is fully blended and the moisture evaporates rapidly by turning the stacker, and material displacement occurs at the same time. Generally, the composting cycle is 7-12 days, and the composting temperature can rise to 60-70 C. In the process control, according to the change of temperature, moisture and oxygen content of compost material, the control system opens the Berek high-pressure fan in Suzhou to aerate in the fermentation tank. After a period of composting, the moisture content of fermented compost decreases greatly (generally to about 40%) and is discharged from the discharging system and transported to the aging workshop. Fermentation composting time will be greatly improved if high-pressure fan is not used for oxygen supply.

Also consider the environmental protection level of the scroll fan, the technical strength of the manufacturer, maintenance level and so on. When we use explosion-proof whirlwind blower, have we found any waste water? How should we deal with it? If we can't solve it properly, what problems will it bring to our work? I believe this is our concern, and we hope our introduction can help you. When we use explosion-proof scroll fan, we also need to turn the fan on, of course, water and testing work can not be less, we also need to see the quality of welding, can not leak, if not check the place, we can use soap water to test. When our fan is running, we also need to see if there is pressure in its lubrication position. If there is no pressure, it can not be recycled. If there is no oil, it is a safety problem for our operation.

Within a certain range of wind turbines, it can be found that it is within the scope of the high-pressure machine itself, so if you can use it safely, the overall advantage is still obvious. The pressure range of Roots blower is relatively large. The pressure of high-pressure Dereike blower is determined by the resistance of the blower. When the resistance in the pipeline increases, the pressure of Roots blower increases. It can be said that the customer can see the value of pressure gauge on the Roots blower is the value of resistance in the pipeline. If the outside world does not exert resistance on the Roots blower, then the Roots blower will have no pressure. It can be said that Roots blower is like a spring. The harder you press it on time, the higher it bounces when you release it. It's no problem that it can reach more than 1 kilogram. So there are many differences between Roots fans and high-pressure fans, not the same kind of fans. In addition, in many industries, high-pressure fans can not replace Roots fans to work, conversely, Roots fans are the same. Of course, every manufacturer's high-pressure fan pressure is actually different.