Regenerative blowers, also known as side channel blowers, are a remarkable innovation in the world of industrial machinery.

These silent workhorses have gained prominence due to their unmatched efficiency and versatility. In this article, we delve deep into the world of regenerative blowers, exploring their mechanisms, applications, and the key factors that set them apart.

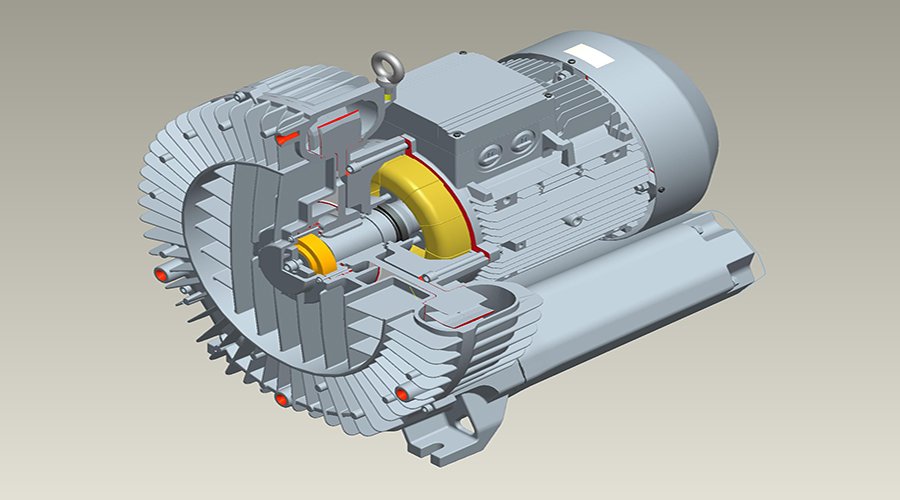

To truly understand the value of regenerative blowers, it's essential to grasp their inner workings. These blowers operate on a unique principle: air is drawn into the side channel, where it is accelerated by impellers. The accelerated air then exits the blower as a high-velocity stream. This continuous cycle generates a constant flow of air, making regenerative blowers exceptionally efficient.

Regenerative blowers find their utility across a wide spectrum of industries. Their ability to provide oil-free, pulsation-free air or gas makes them indispensable in applications such as:

Wastewater Treatment: Regenerative blowers play a pivotal role in aerating wastewater, facilitating the breakdown of contaminants. Their robustness and reliability are crucial in this critical process.

Pneumatic Conveying: The efficient transportation of bulk materials relies on regenerative blowers, ensuring a steady and controlled flow.

Printing and Paper Handling: In the printing industry, precise air control is paramount. Regenerative blowers excel at delivering consistent air pressure, enhancing print quality.

Medical Equipment: Ventilators and dental suction systems benefit from the reliability and quiet operation of regenerative blowers.

Food Packaging: The food industry utilizes these blowers for vacuum packaging, ensuring product freshness and longevity.

Environmental Remediation: Cleaning contaminated sites and soil vapor extraction are made possible by the power of regenerative blowers.

What sets regenerative blowers apart from other options in the market? Here are some key advantages:

Energy Efficiency: Regenerative blowers are known for their impressive energy efficiency, helping businesses reduce operational costs while maintaining high performance.

Minimal Maintenance: Thanks to their straightforward design, regenerative blowers require minimal maintenance, resulting in increased uptime and reduced downtime.

Silent Operation: The low noise levels of regenerative blowers make them ideal for indoor applications where noise pollution is a concern.

Oil-Free Operation: The absence of oil in the air stream ensures clean, uncontaminated air, making regenerative blowers suitable for sensitive industries like food and pharmaceuticals.

Compact Design: Their compact size allows for easy integration into existing systems and saves valuable floor space.

In conclusion, regenerative blowers are the unsung heroes of various industries, silently powering critical processes with their efficiency and reliability. Whether it's wastewater treatment, pneumatic conveying, or medical equipment, these blowers have proven their worth.

Embrace the regenerative advantage and elevate your industrial processes to new heights of efficiency and sustainability with regenerative blowers. Invest in innovation, and watch your operations thrive.