In the world of industrial equipment, medium pressure blowers play a crucial role in various applications. Their design is not arbitrary; it's a result of careful consideration and engineering precision. Let's delve into why the structure of medium pressure blowers is crafted in a particular way.

Significance of Medium Pressure Blowers

Medium pressure blowers are mechanical devices used to generate airflow at moderate pressure levels. They find their applications in a wide range of industries, including HVAC systems, industrial processes, and more. The design of these blowers directly impacts their functionality and efficiency.

Efficiency Matters

Efficiency is a paramount concern in the design of medium pressure blowers. These blowers need to move air effectively while consuming as little energy as possible. The structure is optimized to ensure that the maximum amount of air is moved with minimal energy input, resulting in cost savings and reduced environmental impact.

Noise Reduction

Noise is another critical factor that influences the design of medium pressure blowers. In many applications, especially those involving HVAC systems in commercial or residential settings, noise pollution is undesirable. Engineers carefully design fan blades, housing, and motor components to minimize noise generation, creating a quieter and more pleasant environment.

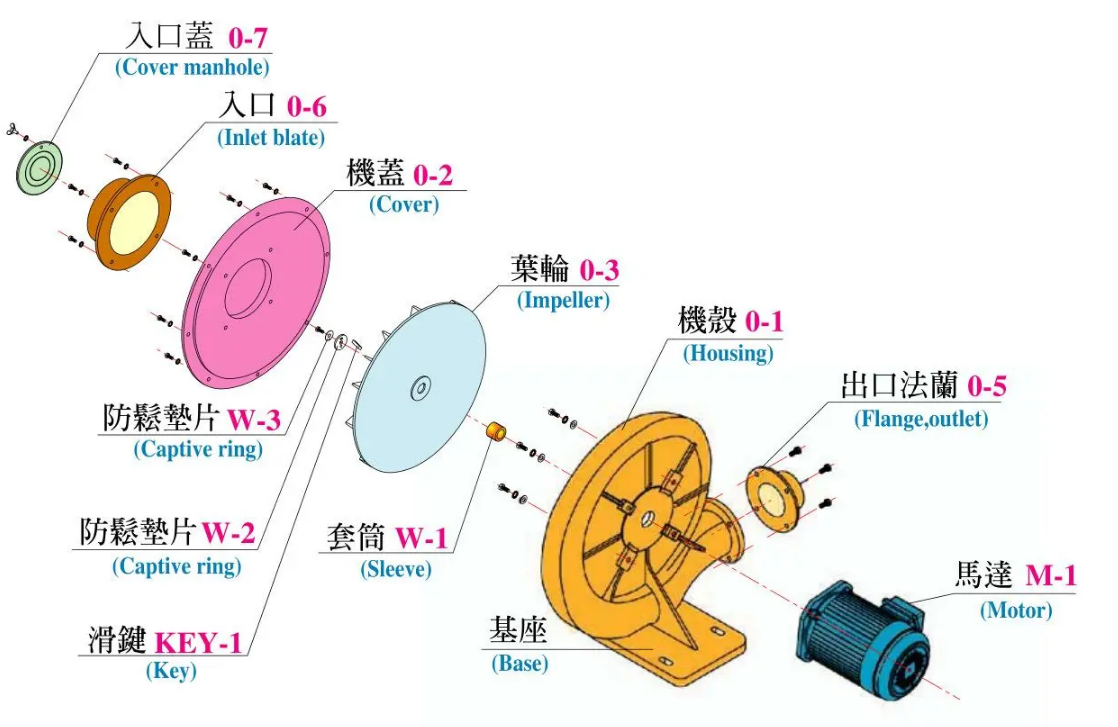

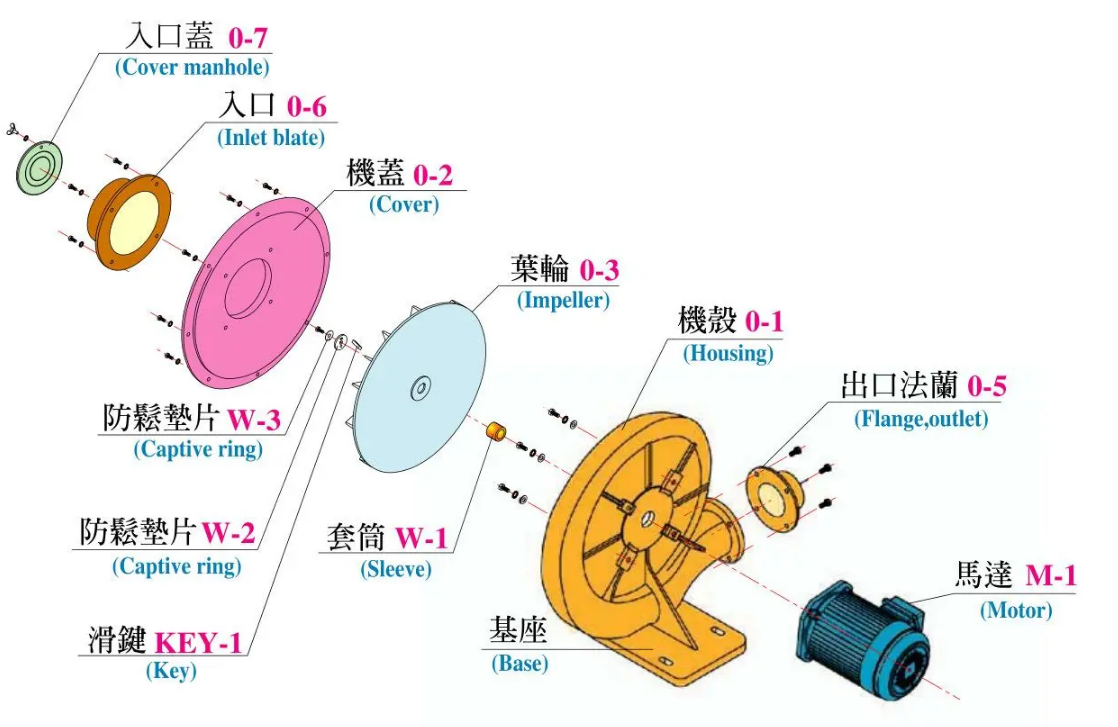

Key Structural Components

To understand why medium pressure blowers are designed the way they are, it's essential to look at their key structural components:

1. Impellers

Impellers are the heart of medium pressure blowers. These rotating blades are responsible for creating airflow. Their design, including blade shape and size, is crucial in determining the fan's performance.

2. Motors

Motors drive the impellers. The choice of motor affects the fan's energy consumption and efficiency. Engineers select motors that match the required power output while minimizing energy waste.

3. Housing

The housing of medium pressure blowers is designed to encase the impellers and motor. It serves multiple purposes, including directing airflow and reducing noise. Proper housing design contributes to efficient airflow management and noise reduction.

Factors Influencing Design

Several factors influence the structural design of medium pressure blowers:

1. Application

The intended application significantly influences the design. blowers used in industrial processes may have different structural requirements than those used in HVAC systems. The design must align with the specific application's needs.

2. Airflow Requirements

The volume and pressure of the required airflow dictate the design's specifications. Engineers calculate these requirements and design the fan to meet them precisely.

Art of Structural Design

Crafting the structure of medium pressure blowers is a delicate balancing act. Engineers consider various factors, including materials, aerodynamics, and noise insulation, to achieve optimal performance.

1. Materials

Choosing the right materials is crucial. Fan components should be corrosion-resistant and durable to withstand various operating conditions.

2. Aerodynamics

Aerodynamics plays a vital role in fan performance. Engineers use computational fluid dynamics (CFD) to optimize blade designs and airflow patterns, ensuring efficiency.

3. Noise Insulation

To reduce noise, engineers incorporate noise insulation materials and techniques into the fan's design. This includes sound-absorbing materials and vibration-dampening mechanisms.

The Benefits of a Well-Designed Blower

A well-designed medium pressure fan offers several advantages:

Energy Efficiency: It consumes less power while delivering the required airflow.

Longevity: Properly designed blowers have longer lifespans, reducing the need for frequent replacements.

Reduced Maintenance: Less wear and tear mean lower maintenance costs and less downtime.

Conclusion

The design of medium pressure blowers is a blend of engineering precision and practical considerations. By carefully considering efficiency, noise reduction, and application-specific requirements, engineers create blowers that play a pivotal role in various industries.