Biological method

Biological treatment is to use the metabolism of microorganisms to convert toxic and harmful organic substances into less toxic substances, and the cost is economical and reasonable. However, coating wastewater is generally high in concentration and contains a large number of toxic organics, which is difficult to be directly biodegradable; Therefore, at present, the combination of physicochemical method and biological method is mostly used at home and abroad, that is, the physicochemical method is used to fully homogenize the water quality and quantity first, so as to reduce the impact load on the subsequent biological treatment.

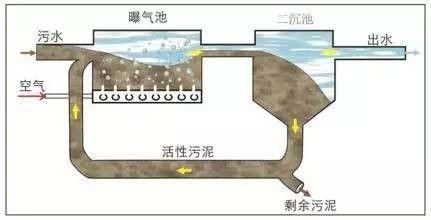

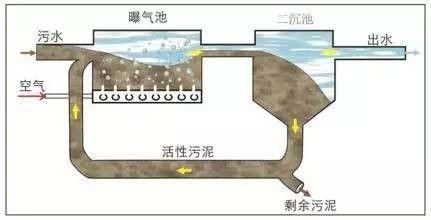

❂ 1. Activated sludge process

In the process of treating coating wastewater by activated sludge method, the coating wastewater and deionized water are combined for chemical flocculation and sedimentation, and then settled in the upflow contact sedimentation tank, and then enter the aeration tank. The original high concentration coating wastewater is lack of nitrogen and phosphorus necessary for microbial growth. It is mixed with domestic sewage to provide the required nutrients. At the same time, a certain amount of special nutrients are added according to the actual needs, which helps to stimulate the growth of degrading bacteria, improve the operation performance of activated sludge treatment system and improve its biodegradation efficiency. The mixed sewage is treated in the activated sludge tank and precipitated in the secondary sedimentation tank. In order to achieve the effect of three-stage filtration, the wastewater from the secondary sedimentation tank is filtered again and the water quality is analyzed. After four months of experimental treatment, the BOD of the original coating wastewater decreased from 15000 mg/l to 21 mg/l, and the total removal rate reached 99 3%。

Wang Fangyuan and others used the oil separation air flotation circulating activated sludge process filtration process to treat coating wastewater. The indicators of the effluent basically met the design requirements, and the total removal rate of COD was about 98%. In view of the difficulty of physicochemical separation of water-soluble solvents in coating wastewater, coagulation filtration can be selected as the pretreatment process, and then flow into the membrane bioreactor with good treatment effect and high degree of automation. After activated sludge aeration biochemical treatment, the COD and SS of the effluent have a good removal effect.

❂ 2. Biofilm method

Biofilm method is to make microbial groups adhere to the surface of other objects in a film shape, which can be purified by contacting with wastewater. Biological rotary table method and biological contact oxidation method with higher biochemical efficiency than activated sludge method are selected to treat comprehensive coating wastewater. Because these two biofilm processes are more effective in treating wastewater with small water volume, high toxicity and many refractory substances.

The U.S. Navy uses more than 1.1 billion liters of harmful wastewater for paint removal every year, mainly containing dichloromethane and phenol; In addition, there are alkanes, cellulose derivatives, petroleum sulfonates and naphthalene. The wastewater and domestic sewage were mixed in a ratio of 1:1, and the comparative experiments were carried out by activated sludge method and biological rotating disc method respectively. The results showed that this kind of mixed wastewater could be effectively treated no matter whether the flora was in suspension growth or adsorption growth. In addition, the activated sludge process to improve the nutritional environment (such as adding glucose to wastewater) can significantly increase the number of flora in the treatment system, which is 2 orders of magnitude higher than when using only a single carbon source. In the biological turntable system, the number of bacteria in continuous water inflow is much greater than that in intermittent water inflow, which may be attributed to two reasons: first, the concentration of toxic wastewater in the reaction system is higher in intermittent water inflow than that in continuous water inflow; Second, continuous water inflow is more conducive to the adsorption of bacteria. In addition, after a comprehensive analysis of the number and species of bacteria and their ability to biodegrade toxic compounds, it is considered that Pseudomonas and rod-shaped bacteria are the dominant bacteria to degrade this kind of wastewater.

(1) Biological turntable

The biological rotary table method has the advantages of easy film hanging, high organic matter removal efficiency, strong impact resistance, low power consumption and convenient management. In order to improve the treatment effect of biological rotary table method, the following factors must be considered. The turntable structure shall adopt multi-axis and multi-stage turntables, and each stage shall operate independently. In this way, even if one stage stops rotating, it will not affect the normal operation of other turntables. Because of the treatment efficiency of stage rotary table, the water inflow at all levels can be reduced step by step at the same time to improve the treatment effect. The assembly method of the rotary table adopts the radiant biological rotary table with honeycomb tubes. Its advantages are that it can adapt to high concentration wastewater, the hydraulic agitation is larger than the general rotary table, the specific surface area is increased compared with the general rotary table, and the oxygenation effect is good. In order to ensure the expected effect of wastewater treatment, the effluent from the biological rotary table is sent to the biological contact oxidation tower for treatment.

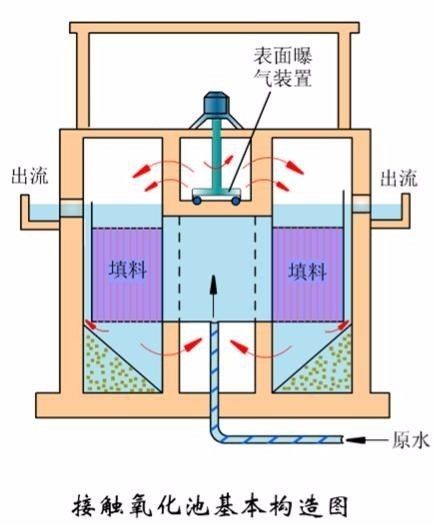

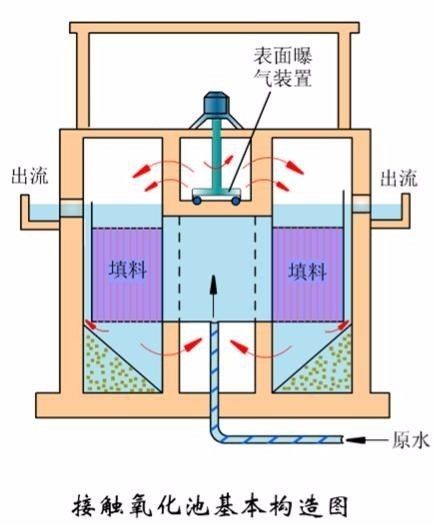

(2) Biological contact oxidation

Biological contact oxidation is a wastewater treatment method that has developed rapidly in recent years. It has the advantages of high treatment load, short residence time, small floor area and no sludge bulking.

In the treatment of coating industrial wastewater, after primary treatment, the treatment process of biological contact oxidation is applied, which has the advantages of short time of microbial membrane domestication, high activity and fast degradation rate of organic substances in the wastewater. The process of homogeneous oil separation, coagulation, air flotation and biological contact oxidation was used to treat the comprehensive coating wastewater, and the effluent reached the national first-class discharge standard. The research of Zuo Hongying and others shows that after pretreatment by flocculation sedimentation and air flotation, and then by secondary biological contact method, the treated water is treated by activated carbon and industrial circulating cooling water processor, and finally meets the design specification requirements of industrial circulating cooling water.

(3) Biological fluidized bed

The biological fluidized bed uses granular materials with particle size less than about 1 mm as the carrier and fills it in the aeration container. The wastewater fluidizes the carrier from bottom to top, and the carrier surface is covered with biofilm. The coating production wastewater is pretreated by primary air flotation and then treated by pure oxygen biological fluidized bed device. It has high efficiency and can be discharged up to the standard.

At present, the moving bed biofilm process (MBBR) and biological aerated filter (BAF) are combined. MBBR has strong impact load resistance, and BAF has the characteristics of integrating biological oxidation and intercepting suspended solids. The two will form a composite biofilm process to treat coating wastewater. After a period of operation, it is found that the treatment effect of the system is good and the operation is stable. When the hydraulic retention time of the single-stage reactor is 5 h and the average influent COD concentration is 800 mg / L, the COD removal rate of the final effluent reaches 93 05%。

(4) SBR process

SBR process is an intermittent activated sludge process. Aerobic bacteria in the device are fully mixed and contacted with sewage. Under the condition of oxygenation, bacteria adsorb organics in water and decompose them into their own components, so as to remove organics from water. Since the aerobic bacteria (activated sludge) will automatically settle to the bottom of the reactor without aeration, the increasing bacteria will be discharged through the sludge discharge system at the bottom of the reactor, separated from the water, and the clarified liquid will be discharged up to the standard.

The SBR operation process consists of five parts: water inflow, aeration, sedimentation, drainage and idleness. Since microbial aeration and sedimentation are carried out in the same container, and the sludge water separation adopts the method of static sedimentation, the sludge water separation effect is good, and the biological retention is high, so the impact load resistance of the device is strong. SBR process has simple structure and no activated sludge reflux and sedimentation system; The operation is flexible, and the operation cycle can be adjusted appropriately according to different products to meet different water quality needs; The device can be equiped, the SBR can adopt steel structure, and the steel structure for small amount of sewage can make installation and maintenance simple and easy to operate; It can adapt to the inlet water quality with great fluctuation.

❂ 3. Oxidation pond

Oxidation pond is a natural or artificial pond, which is a general term for structures that use natural purification capacity to treat sewage. Wastewater stays in the pond for a long time, and organic pollutants are degraded and purified through the metabolic activities of microorganisms in the water.

The application of aquatic plants based ecological pond project to purify coating wastewater is also an efficient biological treatment technology. Huang Yunzhu and others cultivated Eichhornia crassipes in the paint wastewater after physicochemical pretreatment, and the wastewater provided the water and nutrients required for the growth and development of Eichhornia crassipes. Experiments have proved that Eichhornia crassipes has tenacious vitality, good pollution resistance and absorption, and is an excellent anti pollution plant. Its ecosystem uses metabolism to purify wastewater, and has achieved ideal results. Moreover, the process flow of purifying coating wastewater in the ecological pond project is relatively simple, which can purify industrial wastewater mainly composed of acids, alcohols and benzene homologues, including phenol containing wastewater. However, because the treatment effect of oxidation pond is greatly affected by light and temperature, the treatment effect in summer is generally better than that in winter.