Failure analysis of high pressure blower

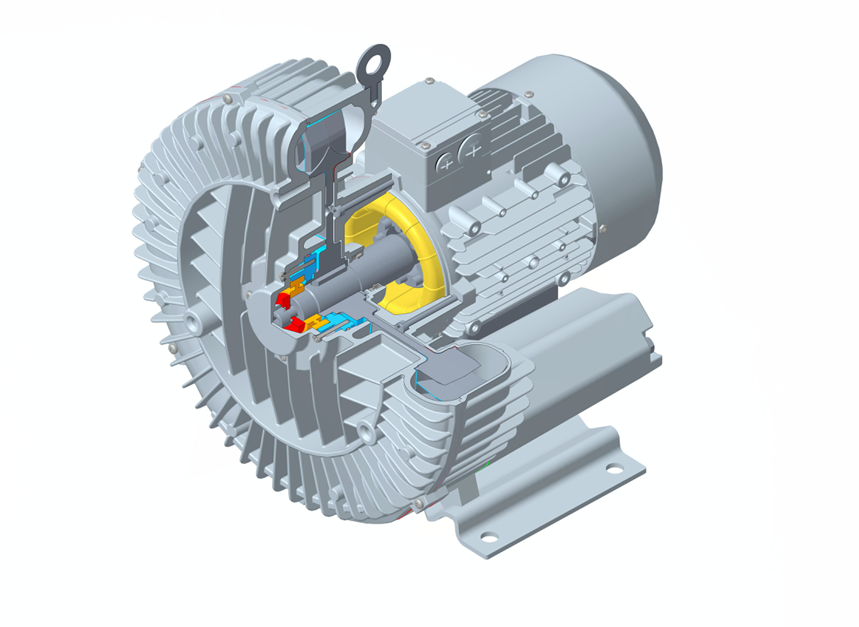

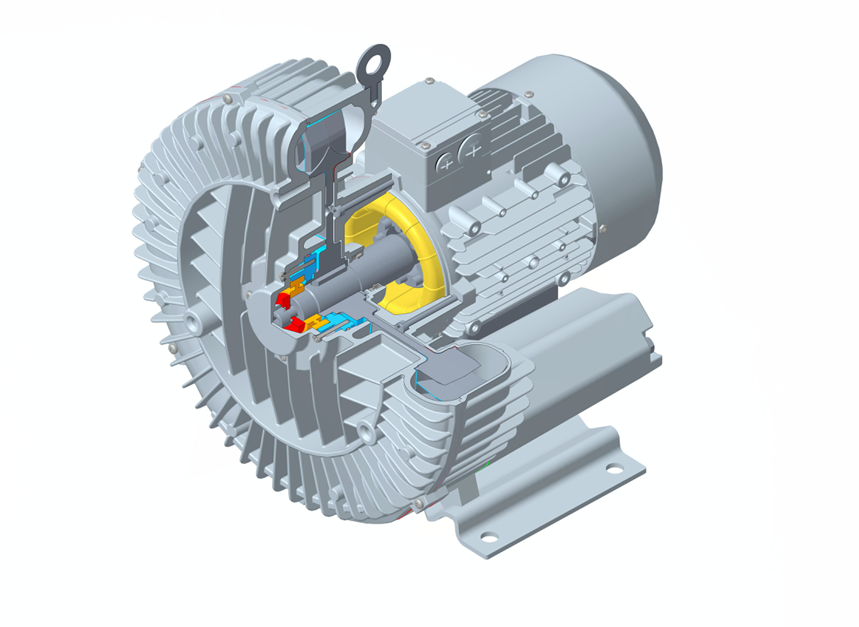

The high-pressure blower is also called vortex air pump and vortex fan. Its principle is that when the air passes through the impeller and side slot along a spiral track, each impeller increases the degree of compression and acceleration. As the rotation progresses, the kinetic energy of the gas increases, which further increases the air pressure passing along the side channel. When the air reaches the connection point between the side slot and the discharge flange (the side channel narrows at the outlet), the gas is extruded out of the blade and discharged from the pump body through the outlet muffler.

Two stage high pressure blower

The faults of high pressure blower are mainly as follows:

High pressure fans need to be protected in two aspects:

1. Pressure: too high pressure will cause no flow in the fan shell for a long time, resulting in too high temperature of the fan and aging of the fan bearing. For the pressure, the relief valve is often used, which is a unloading valve. When the use pressure of the high-pressure fan exceeds the pressure set by the relief valve, the relief valve will open automatically to release the excess pressure, so as to protect the high-pressure fan.

2. Dust: too much dust in the working environment of high-pressure fan will stick to the fan impeller and bearing, which will cause the high-pressure fan to be stuck and cause the fan not to run. For dust, filters are often used. It often uses different filter elements with different filtering accuracy according to different use sites. Different filter elements have different maintenance methods and service life, which need to be asked clearly when ordering.