Side Channel Blowers, often referred to as regenerative blowers, play a crucial role in enhancing efficiency and productivity in chemical processing. In this article, we will explore how to effectively use Side Channel Blowers in this industry for optimal results.

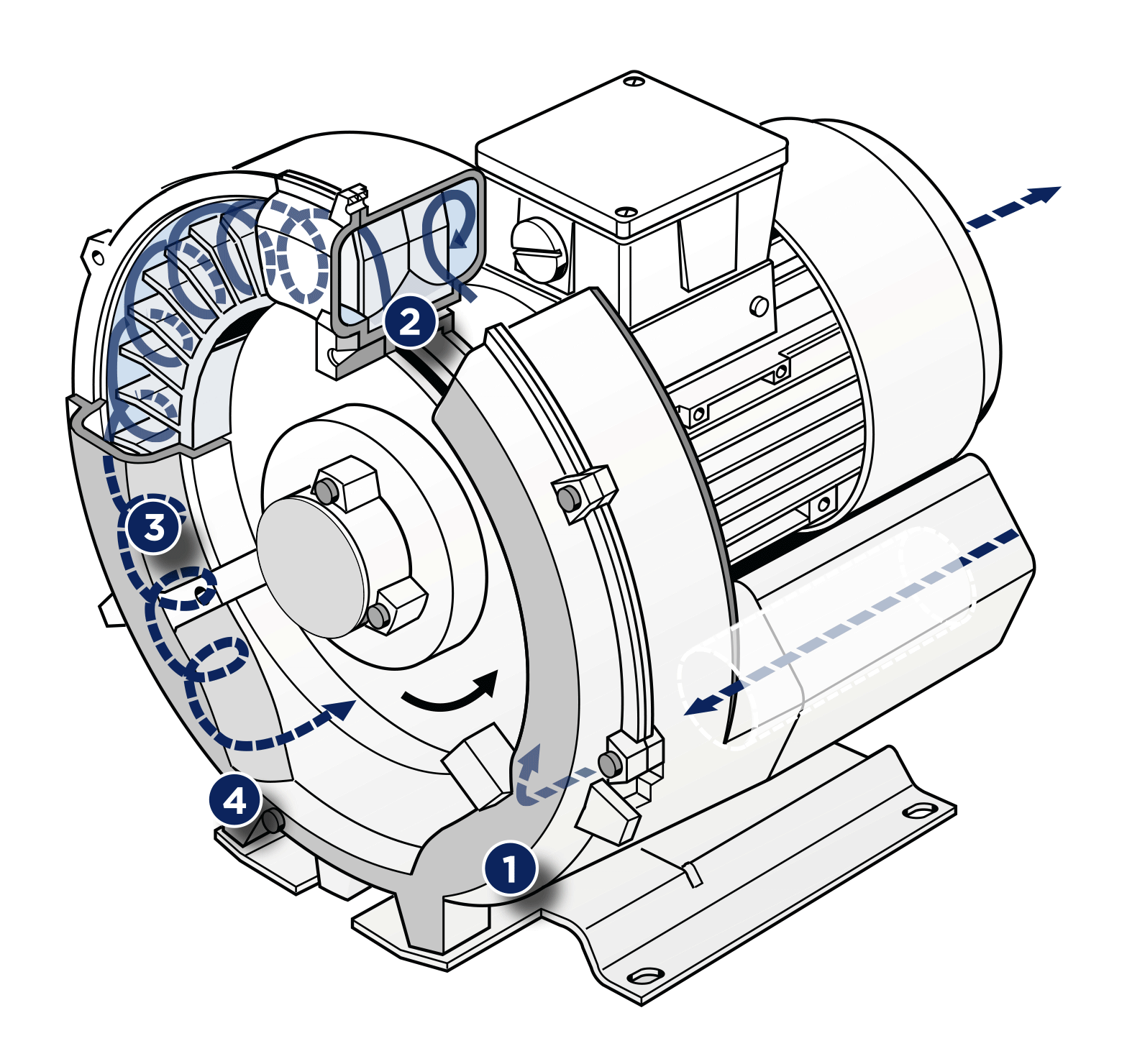

Before diving into their applications, it's important to understand what Side Channel Blowers are. These machines use a unique principle called the regenerative or side channel effect to generate airflow. They are designed for applications requiring high-pressure, low-flow-rate air or gas.

Side Channel Blowers are extensively used in pneumatic conveying systems within chemical processing plants. They facilitate the movement of powders, granules, and other materials through pipelines. Their precise control over airflow ensures that materials are transported efficiently without clogging or degradation.

In chemical processing, maintaining clean and contaminant-free environments is vital. Side Channel Blowers are employed in vacuum filtration systems to remove impurities and collect materials without causing damage or contamination.

Chemical reactions often require precise control of gas and liquid mixing. Side Channel Blowers can be used to provide aeration and agitation in chemical reactors. Their ability to deliver consistent airflow is crucial for maintaining the desired reaction conditions.

Efficient wastewater treatment is a critical aspect of chemical processing. Side Channel Blowers are used to aerate wastewater, promoting the growth of beneficial microorganisms that aid in the breakdown of pollutants. This process helps in reducing the environmental impact of chemical processing plants.

To maximize the benefits of Side Channel Blowers in chemical processing, consider the following best practices:

Proper Sizing: Ensure that the blower is appropriately sized for the specific application. An oversized or undersized blower can lead to inefficiencies and increased energy consumption.

Maintenance: Regular maintenance is essential to keep Side Channel Blowers operating at peak performance. This includes cleaning, lubrication, and inspection of components.

Safety Measures: Implement safety measures to protect operators and equipment. This may include installing safety guards and pressure relief valves.

Monitoring and Control: Utilize monitoring and control systems to adjust airflow and pressure as needed. This ensures that the blower operates within the desired parameters.

Noise Reduction: Install noise-reduction measures if the blower's noise level is a concern in your facility. This can include sound enclosures or dampeners.

Side Channel Blowers are versatile and invaluable tools in chemical processing. Their applications range from material conveying to wastewater treatment, contributing to improved efficiency, reliability, and environmental responsibility within the industry. By following best practices and understanding their capabilities, chemical processing plants can harness the full potential of Side Channel Blowers to achieve their operational goals.